Fully Automatic Vertical Rotary Curved Surface Printing Machine TX-P60-108-208 For Cups

- Model

- TX-P60-108-208

Item specifics

- Printing color

- single color

- Operating mode

- Fully automatic

- Printing speed

- 3600-4800 PCS/H

- Maximum mesh frame size

- 180*450mm

- Maximum Print Area Round

- φ110mm

- Maximum Print Area Oval

- 210mm Arc Length

- Air pressure

- 0.4-0.8 MPa

- Application area

- cups

- Overall dimensions

- L3500 *W2500 * H1950mm

- Voltage/Power

- AC220V 50/60Hz 7KW

Review

Description

I. Introduction

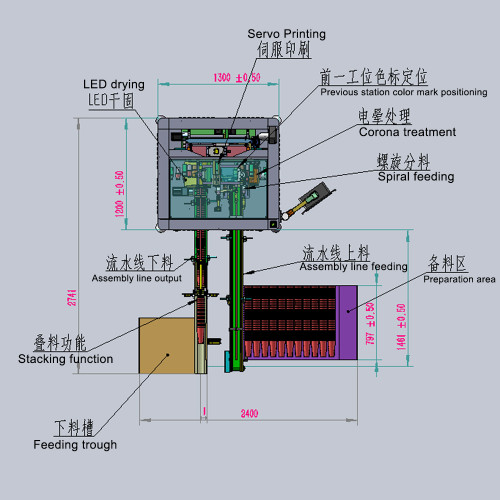

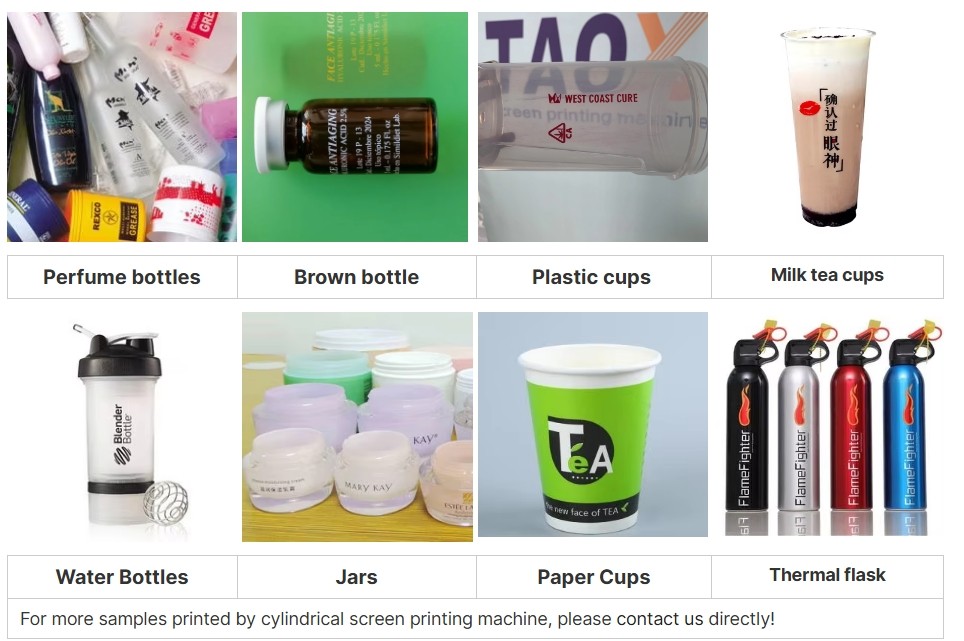

The fully automatic vertical rotary curved surface screen printing machine is a new type of curved surface printing machine, mainly suitable for printing on various cups, bottles and curved surface products. This machine uses a material storage bin for material preparation, online stacking, spiral automatic decomposition feeding, high-precision sensor positioning, electronic cam full-linkage high-speed printing, and a matching instant-drying system for curing. It features automatic air-blowing unloading, online stacking photoelectric eye for precise counting, and a matching finished product stacking bin. The entire mature, fully servo-driven, high-speed, continuous operation system is convenient to operate, simple in structure, easy to use, fast, and saves time, labor, and costs. Furthermore, it can be configured to select single-color or multi-color printing to meet different product requirements.

The equipment is mainly used for printing graphics on the surfaces of daily necessities, cosmetics, food, wine, medical products, rubber, plastics, hardware and electronics, glass, and metal items, and has a wide range of applications.

Features :

1. The entire machine is controlled by a touch screen and a control card program, and the mobile cantilever box allows for flexible operation and is very convenient to use.

2. Fully automatic design, high-speed operation in visual automation mode.

3. Unique spiral material distribution structure and high-speed electronic cam fully continuous operation system.

4. The product undergoes corona surface treatment before printing to improve adhesion. (Select pre-printing method according to requirements)

5. The rotary table has a diameter of 600mm and 8 printing stations; (12 stations are optional depending on the product size).

6. Before printing, the photoelectric sensor locates and positions the points for accurate overprinting.

7. After printing, the products are processed by an automatic quick-drying system, providing efficient and convenient functions.

8. Equipped with loading and unloading storage bins, automatic stacking, and precise counting functions.

9. The machine operates smoothly with high speed and a high rate of human-machine interaction, making it the optimal choice for automation.

II. Machine configuration parameters :

|

Product name

|

Fully Automatic Cup Screen Printing Machine

|

|

Product model

|

TX-P60-108-208

|

|

Application area

|

paper cup,glass cup,plastic cup,coffe cup,milk tea cup

|

|

Printing Speed

|

Monochrome 3600-4800 PCS/H

|

|

Maximum Print Area Round

|

φ110mm

|

Maximum Print Area Oval | Arc Length 210mm |

Maximum print Length | 180mm |

Maximum Screen Frame Size | 180*450mm |

Air pressure: | 0.4-0.8 MPa |

Voltage | AC220V 50/60Hz 7KW |

Dimensions(L*W*H) | 1300 * 1200 * 1950mm; |

Weight | 800KG |

Printing process

Material storage in the silo, feeding via conveyor belt, decomposition feeding via spiral structure (or push feeding), pre-printing treatment with corona (or plasma treatment and flame treatment, optional), LED ink screen printing, LED second curing of printed products, unloading by blowing or clamping, online stacking, counting, and finished product receiving silo.

Note: This model is available in single-color and two-color printing, and two different feeding methods. (Optional based on product)

Printing Samples

IV. Machine Operation Safety Performance

The vertical curved surface screen printing machine is the latest model of cup printing equipment. Please operate it according to the manufacturer's instructions; it is absolutely reliable. This machine is equipped with an emergency switch: in case of an emergency, pressing the emergency switch will immediately cut off the power and return the machine to the starting position; after the problem is resolved, turning off the emergency switch will allow for safe restart and normal operation.

V. Precautions

When the machine needs to be moved or repaired, the power and gas supply must be disconnected.

When adjusting or cleaning the wiper blades, please follow the steps and perform maintenance as scheduled.

Enhance fire prevention awareness and equip facilities with fire-fighting equipment.

VI. After-sales service instructions

①support for all products shipped from our factory .

②After installation and commissioning, it comes with a one-year free warranty (excluding consumable parts and damage caused by human error), and lifetime maintenance.

③We conduct regular visits for maintenance, on-site operation, and technical training.

④After-sales service content:

▲If the equipment malfunctions, please first contact us by phone. If the problem cannot be resolved by phone, our company will arrive on-site as soon as possible to resolve the issue.

▲Our after-sales service includes not only equipment repair and maintenance, but also dedicated support in process technology. Our technical staff can provide on-site technical training and offer a complete set of screen printing process technology, information and equipment solutions.

▲Professional technicians will visit users periodically to monitor the usage of their equipment.

▲Repair and maintenance of screen printing equipment and auxiliary equipment.

Design and customize screen printing equipment and auxiliary equipment for special products.