TX-400UV Curing Machine

- Model

- TX-400UV

Item specifics

- power supply

- 220V/50HZ

- UV segment length

- 150cm

- Total power

- 9KW

- Conveying speed

- 1-5m/min

- Conveyor belt height

- 70mm

- Chief

- 250cm

- gross weight

- 350KG

- Packing dimensions

- 256*80*165mm

- External dimensions

- 250*70*160cm

- Mesh belt width

- 40cm

Review

Description

Introduction of TX-400UV Curing Machine

This UV curing machine is suitable for curing UV inks on medical supplies, mobile phone casings, membrane switches, electronic plastic casings, electronic components, LCD panels, terminal sealing, mobile phone component bonding, plastic component bonding, and LCDs.

Main parameters

Model : TX-400UV

Rated voltage/Power: 220V/50HZ

Dimension Size : 250*70*160cm

Gross weight : 350KG

Features:

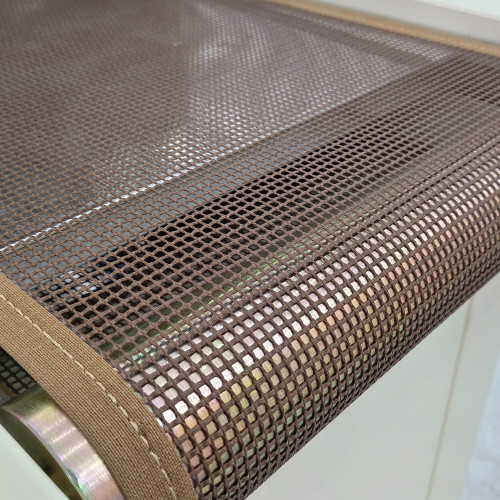

1. The UV dryer features a novel and beautiful design, excellent practicality and operability, and uses brand-name lamps and imported speed-regulating motors. Its curing effect and technical parameters far surpass those of similar products. The operability and controllability of the imported speed-regulating motor fully meet the required requirements. The selected Teflon conveyor belt is both heat-resistant and a highly durable material.

2. The exhaust system uses a horizontal motor, which is installed at the top of the unit. It has strong and uniform airflow and plays a good role in heat dissipation and ventilation.

Usage Steps

1. Open the lamp cover, adjust the lampshade height to the required height for the product, and then close the cover.

2. Turn on the main power switch; the power indicator light will illuminate.

3. Turn on the fan switch; the fan indicator light will illuminate, and the fan motor will start operating simultaneously. (Note: When the fan motor is operating, clockwise rotation is normal; otherwise, the motor needs to be reversed.) Follow the arrow direction.

4. Turn on the speed control motor switch, turn the speed controller, and select an appropriate speed to suit the product usage.

5. Turn on the UV lamp switch. The ammeter will display the current corresponding to the lamp wattage. (If you turn the lamp on and off and then turn it back on, you must wait for the lamp to cool down before restarting.)

6. When the work is finished, turn off the UV lamp first, then turn off the speed control motor, then turn off the fan switch, and finally turn off the main power switch.

7. The top fan motor usually starts turning on 2 minutes after the lights are turned on. (Note: This function is already controlled and does not need to be set again.)

Important Notes

1. Ultraviolet rays can damage the eyes; take precautions.

2. Use industrial alcohol to clean the lamp tubes before replacement;

3. Clean the lampshade and lamp tubes regularly;

4. Change the transmission oil regularly;

5. Check if the exhaust motor is working properly;

6. After two weeks of operation, tighten all screws on the machine.

7. Replace the exhaust filter regularly;

8. The exhaust motor should be used at an appropriate level.